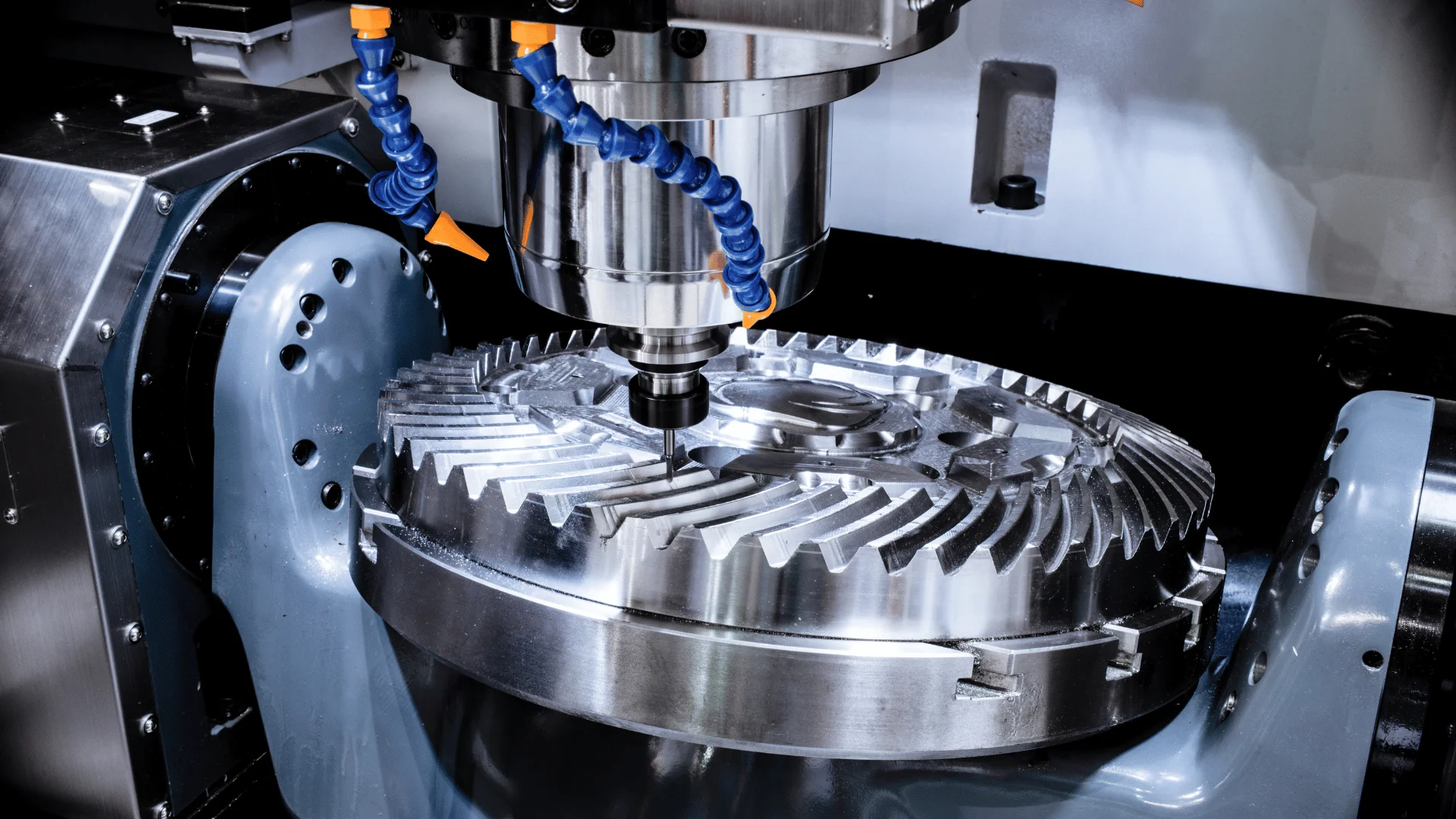

We Offer Revolution Of Industrial Engineering

More Information

+91 9911757222

+91 9911757222

After guiding hundreds of manufacturing decisions over my career in precision machining, I’ve found that choosing between milling and turning often determines a project’s success before the first chip is cut.

Making the right decision isn’t just about technical capabilities – it’s about understanding the practical implications for your specific application, timeline, and budget.

When Milling Delivers Superior Results:

Through years of project analysis, I’ve identified several scenarios where milling consistently proves to be the optimal choice:

Components with irregular external shapes, multiple flat surfaces, or complex contours

Parts requiring features like keyways, slots, pockets, or non-circular holes

Large, flat components with substantial flat areas or plate-like geometries

Production runs in the dozens to hundreds of units

When Turning Is The Better Choice:

Turning offers distinct advantages in several common scenarios:

Components that are fundamentally cylindrical in nature

Parts requiring concentric internal and external diameters

Components with thread features (particularly external threads)

Higher production volumes (thousands of units or more)

At Westa, our comprehensive machining capabilities include both advanced CNC milling and turning, allowing us to recommend and implement the optimal process for each client’s specific requirements. Our engineering team evaluates each project based on geometry, tolerance requirements, material considerations, and production volume to determine the most efficient manufacturing approach.

What separates Westa from many other manufacturers is our ability to combine milling and turning operations when appropriate. Our multi-tasking machine tools can perform both operations in a single setup, maintaining precise relationships between features while reducing handling time and potential alignment errors. This capability is particularly valuable for complex components with both rotational and non-rotational features.

The financial implications of choosing the right manufacturing process can be substantial. A recent project for a resources client illustrates this point perfectly. By recommending a mill-turn approach rather than separate milling and turning operations, we reduced production time by 40% and improved dimensional accuracy by eliminating the need for multiple setups. The result was not only a higher quality component but also a 25% reduction in unit cost.

Whether your project is better suited to milling, turning, or a combination of both, Westa’s team has the expertise and equipment to deliver optimal results. Contact us today to discuss your specific manufacturing requirements and discover how our approach can improve quality while reducing lead times and costs.

Contact Westa’s engineering team for a free consultation on your next precision machining project

WESTA Global

25 FINANCE PLACE MALAGA , WA 6090

83-84, DDA Market, J Block,

Vikaspuri, New Delhi 110018

+91 9911757222

hellowesta@gmail.com

teamtradesate@gmail.com

+61 433 560 490

TRADESATE Pvt. Ltd.

B11/226, Sri Hargobindpur, Punjab 143515

Copyright © 2024 WestaGlobal.